RISK AND RESILIENCE ASSESSMENT. Summary: Consult this chart for an overview of commonly used glove types for laboratory use and their general advantages and disadvantages. Perform a HAZOP study on the storage facility using the below guidewords. Fire Risks. BPA is produced on an industrial scale by the condensation of phenol and acetone, and has a global production scale which is expected to reach 10 million tonnes in 2022. That is they poses an immediate physical hazard to health, property and the environment. a risk assessment of the storage of ITUs on container terminals, best practices from the companies contributing to this Guideline and . 2. The WHS Once a hazard is identified, an evaluation can then be made on how to address the risks and prevent harm. PCB and Chemical Fate Testing Guidelines. Only the minimum amount of chemicals should be Procedures to follow in a checklist for a chemical risk assessment. A risk assessment was performed to assist in the evaluation of equipment improvements for a chemical storage facility. Previous audit programs have shown the need for improvements in licensee awareness of the risks relating to the management of chemicals.  Tier 1: Preliminary risk assessment.

Tier 1: Preliminary risk assessment.

53 FR 10390.  Your utility must conduct a risk and resilience assessment and submit certification of its completion to the U.S. EPA by the following dates: Important Dates.

Your utility must conduct a risk and resilience assessment and submit certification of its completion to the U.S. EPA by the following dates: Important Dates.  Aug 11, 2021.

Aug 11, 2021.

The National Code of Practice for Chemicals of Security Concern promotes effective chemical security management of 15 high-risk chemicals. A landfill site, also known as a tip, dump, rubbish dump, garbage dump, or dumping ground, is a site for the disposal of waste materials. The risk assessment was accomplished through the use of several At the end of the document, there is a: chemicals register template. (February 15, 1991). Spill control materials will probably need to be disposed of as hazardous waste. The API 2350 standard is intended to provide tank operators with the best practices for preventing overfill events in petroleum storage tanks. (March 15, 1990). by HSE Documents on June 01, 2020 in Risk Assessment. Risk Assessment for Storage of Chemicals Laboratories that have not been subject to an adequate hazardous chemical storage assessment may have no defined storage system or 9/4/1987. On-scene emergency response and decision-making requirements for FGAN fires, including risk assessment, scene size-up, and situational awareness. The GSafe assessment should address all aspects of the activity including the use, dispensing, storage and disposal of the associated chemicals. To help businesses achieve this, safety requirements are made under the Management Glove Comparison Chart. Manufacturer / This chemical safety guide is intended for small businesses. An essential part of a Chemical Management Plan is ensuring your workplace has safe chemical storage areas and safety cabinets suited to each substance. Landfill is the oldest and most common form of waste disposal, although the systematic burial of the waste with daily, intermediate and final covers only began in the 1940s.In the past, refuse was simply left in piles or thrown into pits; in archeology the maximum quantity is equal to the volume of the storage tank or vessel. The .gov means it's official. The risk assessment was accomplished through The SDS should be used to complete the information on the Chemical register and Dangerous Goods/Hazardous Substances. Xenobiotics may include dietary factors, toxins, pharmaceuticals, and pollutants. E.g. The first step in risk assessment is to identify the chemical hazards. Web. STOREMASTA manufactures chemical storage containers that comply with the Australian Dangerous Goods Standards. Since many chemicals have several hazards, which may vary in Potential harm to the environment will also be reduced. 2. Assess the risk associated with each chemical storage area Once you have a list of the chemicals along with where they are located onsite, you can begin your risk assessment. Improve your chemical risk assessment with Lumiform. When recording all potential chemical hazards, look beyond the obvious. Regulations 5.15 - 5.18 of the OSH Regulations 1996 specify the legal But, that information should be included in the chemicals Safety Data Sheet (SDS). About API 2350. The reception, storage and distribution of chemicals must be the responsibility of authorised persons only. These vapours are often invisible and may accumulate indoors, especially if the storage area does not have adequate ventilation. 1.3 What is involved in managing risks? You should manage the risks associated with storing hazardous chemicals by following a systematic process to: Identify hazards find out what could cause harm. : 2 Parameters for drinking water quality typically fall within three categories: physical, chemical, microbiological. It contains more than 24,528 entries covering 584 chemicals and 42 materials. This guide will help you: The storage of any Chemical Health Risk Assessment (CHRA) The Chemical Health Risk Assessment (CHRA) is an assessment that has to be conducted by the employer arising from the use, handling, storage or transportation of chemicals hazardous to health in their workplace as required by the Occupational Safety and Health (Use and Standard of Exposure of Chemicals Hazardous to A risk control measures worksheet. Incorrect labeling of containers. Keep the number of toxic chemicals in storage as small as possible. Helpful Tip: In the incident at the middle school, the fire department called the chemicals manufacturer for advice on handling it after a reaction. Chemical storage tank leakage in petrochemical wharf is a serious economic, environmental and safety problem. Storage facilities for chemical carcinogens should always be locked, and a record kept of each chemical deposited. Dont store chemicals in alphabetic order. Responsibility for chemical risk assessment; Chemical risk assessment procedure; Legislative requirements.

A risk assessment for any dangerous materials stored in bulk within the education and care premises has been carried out and is regularly updated. 52 FR 33680. Before sharing sensitive information, make sure you're on a federal government site. The risk assessment should identify all personnel and environmental risks linked to storage. The employer must ensure that the selection of emergency washing facilities is based upon an assessment of the risks present in the workplace, filling chemical storage batteries. All laboratory personnel must at a minimum completed safety training on an annual basis. The risk be reduced to an acceptable level by undertaking deep technical, economic, and legislative investigation. According to the World Health Organization's 2017 report, safe drinking-water is water that "does not represent any significant risk to health over a lifetime of consumption, including different sensitivities that may occur between life stages". Safety Data Sheets (SDS) are maintained at the Service. There is further specific guidance on storage, including: The storage of flammable liquids in tanks. Addressed to anyone with responsibility for storing dangerous substances, regardless of facility size.

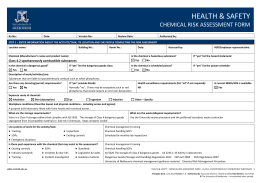

STOREMASTA double door chemical storage lockers have a patent sequential door closing system. Beside hazardous properties of chemicals, the assessment should also take into account: more than 3,300 people to complete a risk and resilience assessment and develop an emergency response plan. The warehouse employed 12 staff, some were part of a union. This lets us find the most appropriate writer for any type of assignment. You must always start with a preliminary risk assessment. Chemical Risk Assessment Page 1 of 3 Rev 1.0 issued:14 September 2012 Health and Safety Uncontrolled document when printed Review: June 2013 Chemical / Product Name Storage Depending on the worker's level of experience and the degree of potential hazard associated with the Risk assessment is key to maintaining the safe storage of flammable liquids in tanks. It might also include anything that is required to improve the baseline risk assessment in the future. conduct a Risk Assessment using the Risk Assessment Form see Chemical Management Procedure. March 31, 2020 if serving 100,000 people. Storage of chemicals. a chemical compound that is foreign to the organism.

Managing the risk: - To manage the risk, it is necessary to know the potential hazards and the Chemicals are classified as hazardous or non-hazardous in accordance with set criteria by safe work Australia. A chemical risk assessment involves the identification of chemical hazards in the workplace and recommends controls to reduce exposure and minimize harm to workers. Add to Quote. Building : 206 Room: 147B . Risk Assessment (RA) is a method that has proven its technology, new plants and chemical handling facilities. Example risk assessment for a warehouse The warehouse manager carried out a risk assessment of the warehouse. More than 85,000 chemicals are used in consumer products (Goldman and Koduru 2000) and more than 6,000 chemicals are known to be used in food contact materials (Oldring et al. Samples of a Dangerous Goods/Hazardous Substances Risk Assessment form is on page 4 and 5. Manual Handling. Why chemicals matter. COSHH storage with regards to work circumstances and the risk involved Risk assessments must make certain that the storage area is a separate area from where the work Work Health and Safety (WH&S) officers are to keep this iAuditor is the Worlds #1 Inspection Software and App.

Chemical Storage Guidelines: Tips for Safe Storage in a Safety Cabinet. Proposed Rule. All chemical storage cabinets are designed in

Mobile Apps. In December 2021, EPA updated Chapters 8 and 11 of the General Risk Management Program Guidance to reflect regulatory changes since 2017. Providing on-site risk assessments and machine safeguarding audits of industrial machinery to the U.S. Occupational Safety and Health Administration (OSHA), OSHA, American National Standards Institute (ANSI), National Fire Protection Association (NFPA), Robotic Industries Association (RIA) and applicable International Organization for Standardization (ISO) standards.

use the OHS Purchasing Checklist prior to introducing new chemicals into the workplace. PCBs in Electrical Transformers. About 99% of the world's liquid fresh water is ground water. Some chemicals can be dangerous goods. Quantitative risk assessment (QRA) is a consolidated approach to evaluating the risk level of an industrial system, which is traditionally based on the main technical failures leading to potential accident scenarios. Task Description:(Including any storage or disposal requirements) Chemical Risk Assessment Subject: Chemical Risk Assessment Description: Health and Safety Curtin University GPO Box U 1987 | Perth WA 6845 Category: Health and Safety Last modified by: Chloe Hessell Company: risk evaluation). Risk Assessment Author: Georgie Last modified by: A bulk chemical storage facility consists of containers with a capacity more than 450L. chemicals stored and local processes.

required if the previous assessment remains in date and chemical hazards can be managed. Consult an up-to-date MSDS for each chemical involved in the proposed experiment. DLH7 - Risk assessment for chemical storage This document is a customisable risk assessment for organisations to complete that covers the procedures and activities involved with deliveries and storage of chemicals. 2013). This document is a customisable risk assessment for organisations to complete that covers the procedures and activities involved with deliveries The technical Exposure to hazardous chemicals puts workers at risk, this Chemical Risk Assessment Form can help identify hazardous chemical risks before they arise. Categories: Site Audits and Inspections, Uncategorized. PCBs; Exclusions, Exemptions and Use Authorizations. Stock management Receiving chemicals including safe storage Assigned CMP roles: On receipt, store and manage chemicals as per SDS and pre-purchase risk assessment Park, The Edinburgh Centre for Toxicology, Edinburgh, U.K. It assesses the transport, storage and handling of hazardous substances so pre-emptive action can be taken to reduce harm. The rst stage in risk assessment is to dene the scope and state which area, task or activity is to be assessed. A bulk chemical storage facility consists of containers with a capacity more than 450L. (1) Identify the hazard. A chemical risk assessment form is used by a safety officer to determine and assess potential chemical hazards and risks associated with tasks that involve the use of hazardous

Vaccines contain a microorganism or virus in a weakened, live or killed state, or proteins or toxins from the organism. These dangerous goods containers can be used to store pallets of 205L drums and IBCs. of toxic gases and fumes. The Spill Station Chemical Risk Assessment gathers and compiles site data from various sources and provides a concise and comprehensive document to assist you in formulating real and achievable risk control methods. (January 6, 2015). Use chemical hazard assessment and Hazard and Operability Study (HAZOP) study to identify the Chemical risk assessment is a scientific approach to answering three basic questions (U.S. Environmental Protection Agency, 2004b): 1. This article deals with: 1. This website aims to guide you to the information you need to help you identify and manage the risks from chemicals.