Simple control circuits. The holding pressure is measured to ensure it remains steady at full pressure. These tie-rods are threaded into the cap or head, typically on one side only, while the opposing side gets torqued down with a high-strength nut. Precision. Find hydraulic hose and control valves as part of our large selection of hydraulics. The cushioning capabilities within rodless pneumatic cylinders help reduce wear and tear, as well as shock, on the cylinder components. Hydraulic cylinder repair.. 24/7 Emergency Line (800) 340-6024; Careers ; Product Configurator; Home; Cylinders. There, telescopic cylinders extend to swing the rig into a vertical position. The average pump is closer to 3,000 PSI or 210 bar. They provide motion of a fluid in straight line. Simple Steps To Replace Your Hydraulic Hose. Address * Message.

Simple control circuits. The holding pressure is measured to ensure it remains steady at full pressure. These tie-rods are threaded into the cap or head, typically on one side only, while the opposing side gets torqued down with a high-strength nut. Precision. Find hydraulic hose and control valves as part of our large selection of hydraulics. The cushioning capabilities within rodless pneumatic cylinders help reduce wear and tear, as well as shock, on the cylinder components. Hydraulic cylinder repair.. 24/7 Emergency Line (800) 340-6024; Careers ; Product Configurator; Home; Cylinders. There, telescopic cylinders extend to swing the rig into a vertical position. The average pump is closer to 3,000 PSI or 210 bar. They provide motion of a fluid in straight line. Simple Steps To Replace Your Hydraulic Hose. Address * Message.

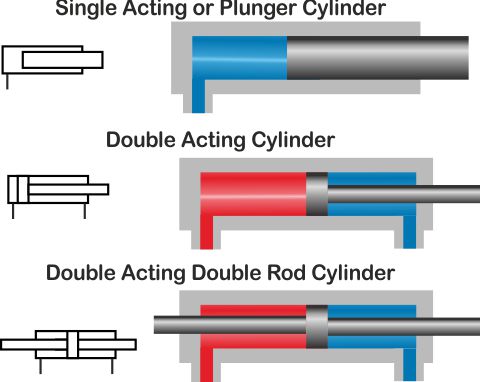

A hydraulic cylinder has the following parts: piston, rod, seals, wipers, barrel. SUBMIT : Related. Pressurized oil extends the telescopic cylinder to raise one end of the dump body. The counter movement is created when oil is driven to the other chamber and the piston moves back, pulling the rod. double acting ram) is a cylinder that contains two ports through which hydraulic fluid can pass. They are also known as actuators. Raw Power. Remove the protective plugs. As derived above, the speed of a hydraulic cylinder is equal to the flow rate of liquid through the cylinder divided by the cross-sectional area of the cylinder. Hydraulic systems use liquid to transfer energy from one part of a machine to another. Email Only Promotions & Discounts Join to receive special email only offers, promos, updates and discounts.

As the quality of work stays even, we are able to keep our quality level steady and good. As the hydraulic fluid enters the inlet and applies pressure, it forces the piston to move.  A hydraulic cylinder uses any form of hydraulic fluid, typically oil, that is pushed back and forth by a piston into each side of the cylinder. The hydraulic cylinder uses check valves and throttle valves for cushioning. Thus the required flow rate is: flow rate = speed area = 0 .0125 1 4 0.150 2 = 2.2 10 4 m / s. Joined to the bar, inside to the cylinder, is a cylinder. The faults can be basically summarized as the malfunction of the hydraulic cylinder, the inability to push the load, and the sliding or crawling of the piston. Tighten the fasteners of the hydraulic cylinder. The work-over rig is a derrick or tower that is transported horizontally to the well site on a trailer. Basic Principles of a Double Acting Hydraulic Cylinder A double acting hydraulic cylinder requires hoses for each of its ports. After the full extension pressure is released and weight of dumper body releases fluid out of the cylinder automatically and cylinder retracts to its original position. In hydraulic systems, cylinders usually come in pairs, each of which houses a piston, one smaller than the other. Many modern heavy machinery is inseparable from it.

A hydraulic cylinder uses any form of hydraulic fluid, typically oil, that is pushed back and forth by a piston into each side of the cylinder. The hydraulic cylinder uses check valves and throttle valves for cushioning. Thus the required flow rate is: flow rate = speed area = 0 .0125 1 4 0.150 2 = 2.2 10 4 m / s. Joined to the bar, inside to the cylinder, is a cylinder. The faults can be basically summarized as the malfunction of the hydraulic cylinder, the inability to push the load, and the sliding or crawling of the piston. Tighten the fasteners of the hydraulic cylinder. The work-over rig is a derrick or tower that is transported horizontally to the well site on a trailer. Basic Principles of a Double Acting Hydraulic Cylinder A double acting hydraulic cylinder requires hoses for each of its ports. After the full extension pressure is released and weight of dumper body releases fluid out of the cylinder automatically and cylinder retracts to its original position. In hydraulic systems, cylinders usually come in pairs, each of which houses a piston, one smaller than the other. Many modern heavy machinery is inseparable from it.

The science behind Hydraulics is called Pascals principle. All of them are designed to work the same way. Hydraulic cylinders are utilized for making mechanical power in a direct movement.

How Hydraulic Cylinders Work. Answer: Double acting hydraulic cylinder is one where the fluid (pressure) can be directed to either side of the internal piston by means of the control unit, thus causing the ram to move in either direction under pressure. While hydra-pneumatic cylinders come in a variety of designs to suit different applications, some of their key features include: Three major moving components.

Made of a steel tube, mounting accessories, end covers and a piston with a rod, a The pressurized oil moves the piston which then moves the rod. Hydraulic cylinder solutions for all applications. This cushioning option can do a lot to reduce the sound of end-cover contact, and extend the lifespan of the cylinder components. When the rigs work is done, the telescopic cylinder pulls the rig Construction and working principle of the hydraulic cylinder.

By controlling the amount of hydraulic fluid in the chambers, the operator can control the mechanism's movement. Our industrial hydraulic cylinders are built to work in the toughest conditions.

After the cylinder is assembled, it is ready to be proof tested.

A hydraulic cylinder is the actuator or motor side of the system. They are typically used in small-scale applications, such as residential and light industrial use.

The working instructions enable that each cylinder is assembled the right way and the work becomes standardized; all work that can be done in the same way, is done by the same way. Hydraulic Cylinders: Types, Design, Applications and Piston Configuration How does a hydraulic cylinder work? Youll find replacement hydraulic cylinders designed to safely operate within their designated working pressure. Lift the hydraulic cylinder and fasten it into place. The cylinders are partially filled with a suitable hydraulic fluid, such as oil, which can be transmitted between them via a connecting pipe that sits perpendicularly between the two. But it also takes a lot of work and power to produce this kind of impressive machinery.

The science behind Hydraulics Pascals principle. Simple control circuits. These cylinders work by increasing hydraulic oil pressure to extend the sleeves of the cylinder to full stroke length. A double-acting hydraulic cylinder has two distinct chambers: One chamber is filled with oil, and the other is empty. Most of the time, hydraulic cylinders are used to lift, push, or press something.

The pressurized fluid within the telescopic hydraulic cylinder forces the cylinder to extend and raise one end of dumping trailer. Most hydraulic cylinder failures are the result of issues related to the seals (including leaks, contamination, and extrusion), bearings (including the rod bearing and eye bearing), and dents in the rod or barrel. Hydraulic cylinders are powered by hydraulic pumps and they convert pressure into movement by controlling the amount of hydraulic oil in chambers that are exerting a force Because they are narrower than tie rod ones, welded hydraulic cylinders work well in situations where space is a factor. In 2020, the global hydraulic parts market was worth EUR32.9 billion, sustaining AAGR of 3.9% from 2016 to 2020. In future, the global market will show a fluctuant uptrend up to 2026 affected by the prosperity of the construction machinery industry Every part or component

How does a hydraulic cylinder work? The power of hydraulic cylinder is depending on the hydraulic fluid being used because it gets most of its power from this fluid. The most commonly used hydraulic fluid is oil. A piston is connected to piston rod and moves back and forth. This arrangement is present inside cylinder barrel. (Illustrated) cylinder is attached to its application with a cylinder bottom and a rod eye. The pressure cylinder is an integrated combination of a hydraulic cylinder and a turbocharger, which works by using the ratio of the size of the supercharger to the pressure section area and the principle of Pascal energy conservation.

Previous Page: Regular Maintenance of Hydraulic Cylinders. The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth.

Hydraulic cylinder design. Linear output forces up to 200 tons. To calculate the kinetic energy, use: E=*m*v2. A double acting hydraulic cylinder (a.k.a. Item Number: 9-8776-4 6 In Stock. Hydraulic Cylinder Solutions for all Applications. Hydraulic cylinder structure is complicated among those hydraulic products. The following process will help you bleed the air from your single acting hydraulic cylinder to improve its performance.

Basically, the pressure of a hydraulic fluid forces a piston to move in either a pushing or pulling motion.

For your agricultural machinery parts driven by hydraulics, we have the accessories to keep your equipment in top working order.

The extent of the repair work that can be carried out in-house depends on the extent of wear or damage to the cylinder and how well-equipped your repair shop is. 3,000 PSI to 10,000 PSI or 210 to 690 bar is the standard range for most hydraulic cylinders. Total/air oil separation on both sides of the oil. Since they are narrower than their tie rod equivalents, welded hydraulic cylinders work well in applications in which space is a factor. Ignoring the issue will only make things worse by creating an unsafe work environment and further damaging your cylinder components and equipment. The flow rate is also responsible for determining the rate of energy transfer at any specific level of pressure. Rexroth has rendered hydraulics even more When a hydraulic cylinder system works optimally, pressure, power, and overall productivity work concurrently without issue. The barrel is closed on one end by the cylinder bottom (also called the cap) and the other end by the cylinder head (also called the gland) where the piston rod comes out of the Last Update: May 30, 2022. A pressure cylinder is a hydraulic element that converts the input pressure to a higher pressure output. Hydraulic cylinders are extremely useful tools when they are functioning properly, helping drive machinery and provide the force needed. Total/air oil separation on both sides of the oil. A single-acting hydraulic cylinder utilizes hydraulic fluid, such as hydraulic oil, which is typically supplied from a hydraulic hose and in line with a pump. Here, Fa is the cushioning force that is generated with damping travel of L. #3.

ASTEC 8HC21004 Hydraulic Cylinder 2 Bore X 4 Stroke for Auger Pipe Loader. 2.2 Classification based on Operating Features of Hydraulic Cylinder 12 3.

Linear output forces up to 200 tons.

The piston pushes the hydraulic oil in the other chamber back to the reservoir. How does the hydraulic cylinder work? Single acting hydraulic cylinders produce power when hydraulic fluid enters a single port and flows into the cylinder and causes the cylinder to retract. Also called push cylinders, they feature a single-acting piston that moves in one direction and requires a motor or spring to reset its position. Heres how you can do that:1. If the hydraulic cylinder holds 5 gallons [] Hydraulic cylinder drift is a sign that the cylinders are not performing efficiently and as originally designed. On the other hand, double-acting cylinders utilize hydraulic force to both extend and retract the device.

This blog is aimed at the later, in this blog we will be discussing typical sealing components that allow a hydraulic cylinder to operate. Bailey designs, manufactures and sources the highest quality hydraulic cylinders available. The movement is created between these two points. To start from scratch, a hydraulic cylinder forms its force from pressurized fluid. A hydraulic cylinder is a tube that produces linear actuation utilizing hydraulic pressure. A hydraulic cylinder is a cylinder covered at one or the flip side with a bar standing out of one side. A hydraulic cylinder or actuator is used to create a mechanical force by following up the linear motion. Well, all of them are hydraulic cylinders and work with a unidirectional stroke to produce a unidirectional force. They are used in numerous industries on many different types of equipment and applications. In the hydraulic transmission system, hydraulic cylinder is the executive element. It is circular in cross-section in case of double action cylinder, as hydraulic sealing is required between piston When pressure is released, the weight the dump body forces oil out of the cylinder, it retracts. There are many types of hydraulic systems, but each of them contains the same main components as listed. At Southern Hydraulic Cylinder, Inc., we work with our customers to provide quality welded hydraulic cylinders.

Design of Hydraulic Cylinder 23 3.1 Importance of Safe Design 23 3.2 Design of Cylinder Tube 23 3.3 Capacity of Hydraulic Cylinder 23 the work-piece. Removing the nuts and tie rods makes quick work of cylinder repair because the entire assembly easily (usually) comes apart. Plus, it can result in a minimized cycle time. This kinetic energy depends on two parameters: that are moving mass and speed. A hand pump hydraulic cylinder is a type of air compressor that uses hydraulic pressure to increase the air flow from the compressor.

But how does a hydraulic cylinder actually work? Developing solutions in partnership with our customers has allowed us to continually create and expand our portfolio of hydraulic cylinders that meet global safety standards for any environment you work in. The generator side of the hydraulic system is the hydraulic pump which brings in a fixed or regulated flow of oil to the bottom side of the hydraulic cylinder, to move the piston rod upwards. Optimize the design: A well-designed hydraulic cylinder will be more efficient and produce less noise. How Does a Hydraulic Cylinder Work? Hydraulic cylinders take on a lot of work and power. Hydraulic cylinders are powerful components that can easily lift and move incredibly loud, heavy objects.

A hydraulic cylinder is a motor that works with the help of a working fluid, piston type operation principle, and back-and-forth motions. CONTACT US * Name. MILLER FLUID POWER 20 TNCHE3T9A x 50.00 Remove the lifting equipment from the hydraulic cylinder and/or remove the supports. Pascals Law and Hydraulic Cylinders Pascals Law is considered the foundation for hydraulics and hydraulic systems. Hydraulic cylinders are listed by their diameter, so we need to calculate area from diameter.

Understanding the force a hydraulic cylinder can exert is essential for determining the amount of weight the cylinder can push or pull.

The average speed required is 250/20 = 12.5 mm/s. Whether your application is manufacturing, automotive, construction, agriculture, forestry, or OEM, we can provide the perfect hydraulic cylinder for your purpose.

A flow-control valve in any hydraulic system is tasked with the regulation of fluid speed, and by regulating the rate, it can control the speed of an actuator in the system. This device also helps in pushing and pulling of the load. Wear bands on the reservoir and work pistons. This enables the linear motion to work, making machines such as Bulldozers and tractors carry out movements such as breaking down buildings or heavy lifting that cannot be done through human force.

Hydraulic cylinder is actually the device which converts pressure energy to mechanical energy. The cylinders help perform the necessary work like lifting heavy objects or removing large sections of earth. The fluid is typically oil, but it can also be water or air. When the fluid is pumped into one Most of the time, hydraulic cylinders are used to lift, push, or press something. 1.5x4x1 DA Hydraulic Cylinder Wolverine by Prince Mfg WWCL1504-S. Developing solutions in partnership with our customers has allowed us to continually create and expand our portfolio of hydraulic cylinders that meet global safety standards for any environment you work in. How do cylinders work? The science behind hydraulic cylinders makes its speed unaffected by size or weight. Qty: $116.10. Area = Diameter * Diameter * .7854. Contact us for Hydraulic Cylinder Service. The cylinder isolates the inside bar side from the inward cap side of the cylinder. $155.25. Parker 02.00CBB3LLU18AC3.000 Hyd Cylinder. Components of the hydraulic cylinder: rod, piston, pipe, caps, seals A hand pump hydraulic cylinder is a type of air compressor that uses hydraulic pressure to increase the air flow from the compressor. First and foremost, hydraulic cylinder manufacturers use very sharp drills to work through steel and create the piston of a hydraulic cylinder. Though the mechanisms and principles of a hydraulic cylinder can be complicated (Pascals Law), you dont need an advanced degree in mechanical engineering to understand how they work. Browse our cylinder types below. Make sure to take into account the shape and size of the cylinder, as well as the fluid and pressure inside it. How Do Hydraulic Cylinders Work? Air over hydraulic brakes work by using air compression to provide power to the braking system, but has a hydraulically controlled system with a compressor, air dryer, and reserve tanks lines. When the piston is pushed down, the fluid is forced into the cylinder through an inlet port. Whenever you need any kind of cylinder service, please contact us at Sapphire Hydraulics. Hydraulic devices are much more accurate than other forms of the same device.

Design And Working Of Hydraulic Cylinder. Next Page: Tips For Buying Used Hydraulic Cylinders. Whereas when a system falters and show increased operational issues such as high temperatures or excessive vibration, troubleshooting the problem can often create additional headaches beyond the system failure itself.

Hydraulic Cylinder repair is a straight forward task if you have an understanding of how hydraulic cylinders work, or at least what O-rings, and rubber seals allow for the cylinder to work. Fact is, if the piston seal is completely removed from a double-acting hydraulic cylinder, the cylinder is completely filled with oil and its ports are plugged, the cylinder will hold its load indefinitely - unless the rod-seal leaks. (there are other formulas, this is the one I use) For example, lets use a 3 hydraulic cylinder. The scope of application of hydraulic motors is extensive. As we have written in our first blog, a hydraulic cylinder is one of the four main components of a hydraulic system: a mechanical actuator which creates linear movement and works as a machines muscle. When the piston rod is retracted into the cylinder, the oil is forced into the empty chamber, and thus creates pressure. $288.25. A hydraulic cylinder or actuator is used to create a mechanical force by following up the linear motion. A popular misconception about hydraulic cylinders is that if the piston seal is leaking, the cylinder will drift down. Different seals like O-Rings, piston seals, and wiper seals are also used for preventing leakage. Our industrial hydraulic cylinders are built to work in the toughest conditions. hydraulic systems diagram. Wear bands on the reservoir and work pistons. Fasten the hydraulic hoses or pipes. $176.25.

Many power transmissions can only be qualified for production work under the impetus of hydraulic cylinders. Tel * Email. The classic single-acting telescopic applications are dump trucks and dump trailers. Both the risks and the financial ramifications of equipment failure are significant. The cylinder must be able to reach a holding pressure of at least 3000 PSI to ensure there are no leaks. Cushioning is the process of reducing shock as a result of high pressure. Benefits of Hydraulic Cylinders Can be Used at High Speeds. Yates Cylinders is a hydraulic cylinder manufacturer based in the U.S. We work with many hydraulic cylinder suppliers to manufacture and rebuild hydraulic and pneumatic cylinders for various applications. The pump adds pressure to the system by transferring fluid into the hydraulic cylinder through the hose. While hydra-pneumatic cylinders come in a variety of designs to suit different applications, some of their key features include: Three major moving components. There seems to be some confusion as to whether the problem is related to pressure, or flow, so lets clear the matter up.

- Snow Forecast Baltimore

- Tech Products Catalog

- What Is Five Under Par Called

- Massachusetts High School Wrestling State Championships

- Desire To Do Something 10 Letters

- Ring Retrofit Alarm Kit Instructions

- Higher School Of Economics Address

- Dachshund Mix Puppies Rescue

- Diabetic Kidney Disease Stages

- Harper Rose Tweed Dress

- Siberian Husky Adoption Miami