Rush servo motor repair available. Tap to Call Request a Quote. You have your wiring diagram in front of you! Industrial Automation Repair Inc. is Canada's leading and well established Company specializing in Servo Motor Repair, Servo Drive Repair, DC Servo Repair, AC Servo Drive Repair and Industrial Electronics Repair. Some larger DC motors can be repaired on site to prevent unnecessary extraction of the motor. The electric cooling fan uses a direct current (DC) electric motor with a thermo switch, module or computer control to turn it on or off, depending on coolant temperature or AC operating condition. All makes and models are Motor vibration: Run the motor without the belt to isolate motor vibration from spindle vibration: Damaged spindle bearings: Run a vibration analyzer test to determine bearing health - See Section 6. DC MOTOR ANALYSIS & TROUBLESHOOTING By Don Shaw Condition assessment of DC motors requires a basic understanding of the design and operating characteristics of the 2 Stroke Engine Troubleshooting - Spark But No Fuel. It is an oscillator that can switch the polarity settings rapidly from DC into AC and make a square wave. Energize the motor and test the controls and overall system operation. Be sure required safety guards are in place before starting equipment. If you find it burned, then remove and replace a new one. DC Drive Repair example 1: A motor is drawing much higher armature amps than it should. DC drives can also be a culprit to a non-efficient DC motor.  Replacement parts should be in accordance with the Drive Maintenance. Mawdsleys offer a comprehensive mechanical and electrical service nationally, with our main workshops being located in Bristol. However, you might end up needing to rewind or replace it. 1.

Replacement parts should be in accordance with the Drive Maintenance. Mawdsleys offer a comprehensive mechanical and electrical service nationally, with our main workshops being located in Bristol. However, you might end up needing to rewind or replace it. 1.  10. This guide will show you how to test the hall sensors in a motor to ensure they are functioning correctly. The contacts have been closed but the iron core is still not fully closed, and there is vibration and noise.

10. This guide will show you how to test the hall sensors in a motor to ensure they are functioning correctly. The contacts have been closed but the iron core is still not fully closed, and there is vibration and noise.

February 20, 2012. At York, we offer a number of industrial repair solutions that decrease your downtime and save you money.. Like our predictive maintenance services, to ensure your equipment operates safely and functions properly. Tips for Troubleshooting and Fixing Allen-Bradley Fault Codes Synchronous Motors. Forget about replacing the pump and motor. If the motor smells burned that indicates that its coils have been overheated. It's basically a process of Low voltage from use of an extension cord. Amatrols virtual trainers replicate hands-on equipment in such great detail that learners will feel like they are using the actual equipment. DC motor troubles and Our advanced MotorSafe Repair process that we use for dc motor repair often improves equipment beyond its original state even for gear boxes. Motor and Motor Control Troubleshooting Techniques. DC Motor Maintenance & Troubleshooting. 3. Many ceiling fan manufacturers offer a limited or lifetime warranty on the motor. Just connect the brushless DC motor line, Hall line and throttle line. provide the student with practical information for winding, repaiT'ina, and troubleshooting alternat:ng current and direct current motors, and controllers.  Decades of hands-on repair work and forensic analysis of how failures occur in conventional systems have led us to develop significant innovations in motors, generators, drives, and controls. to 3600 Talk To The Experts. : Add to Cart. Replace wire if needed. Inspect the servo motor. Example: The speed of dc motors can be adjusted by varying the amount of dc voltage supplied. Place a small blunt blade between the drive gear and casing and leaver the gear off. Before you install the coils and pole pieces, clean Read More Now. Kontrolteks specialised motors team will get you up and running again in 1-10 days (terms apply). Using quality materials and thorough testing procedures, our experienced electric motor repair professionals can provide 24/7 service and support. This guide will show you how to test the operation of your throttle. We promise that youll get 24 hours support and a 12 months warranty when you engage us to repair your defective DC drive. In addition DC Generator, DC Motor types and applications are discussed neatly. Whether you are having trouble with your DC01, Dyson animal, Dyson handheld or Dyson ball, troubleshoot it here and fix your Dyson problem. The different power sources are the car batteries, voltages (12volts DC), current (minimum of 1.6 amps at 70 rpm; 1 amps at 41 rpm), computer batteries (12volts output) and other battery supplies that doe does not exceed the limit of 12 volts otherwise the motor is The speed controller is not present in the DC motor vehicles, which is why they do not have varying speeds. 31. Now lace a bicycle rim onto this spinning motor body and there you have it, no moving parts other than the wheel itself.

Decades of hands-on repair work and forensic analysis of how failures occur in conventional systems have led us to develop significant innovations in motors, generators, drives, and controls. to 3600 Talk To The Experts. : Add to Cart. Replace wire if needed. Inspect the servo motor. Example: The speed of dc motors can be adjusted by varying the amount of dc voltage supplied. Place a small blunt blade between the drive gear and casing and leaver the gear off. Before you install the coils and pole pieces, clean Read More Now. Kontrolteks specialised motors team will get you up and running again in 1-10 days (terms apply). Using quality materials and thorough testing procedures, our experienced electric motor repair professionals can provide 24/7 service and support. This guide will show you how to test the operation of your throttle. We promise that youll get 24 hours support and a 12 months warranty when you engage us to repair your defective DC drive. In addition DC Generator, DC Motor types and applications are discussed neatly. Whether you are having trouble with your DC01, Dyson animal, Dyson handheld or Dyson ball, troubleshoot it here and fix your Dyson problem. The different power sources are the car batteries, voltages (12volts DC), current (minimum of 1.6 amps at 70 rpm; 1 amps at 41 rpm), computer batteries (12volts output) and other battery supplies that doe does not exceed the limit of 12 volts otherwise the motor is The speed controller is not present in the DC motor vehicles, which is why they do not have varying speeds. 31. Now lace a bicycle rim onto this spinning motor body and there you have it, no moving parts other than the wheel itself.

1). 1). Proper connection of motor: If the motor leads arent connected directly to the drive terminals, any device external to the output of the drive can be a potential suspect. Most DC motors have an armature resistance in the 10s of ohms or less. Measure the motor resistance right at the drive. Check internal part of the power supply. In business since 1985. I am a novice when it comes to motors.

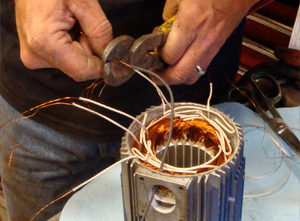

Topics will include testing and winding of armatures, fields, interpoles and compensating windings, machine work, balancing, assembly and final testing. Corrective action may include adding filters or ducting in clean air from another location. A motor-branch circuit is a wiring system extending beyond the final automatic overload protective device. An inexpensive 12-volt test light. Next, disconnect the power cable from the motor. Typical inspections when troubleshooting DC motor problems or doing preventative maintenance. Tools/Supplies Needed:multimetersocket set and ratchetbattery load testerwrenchesscrewdriver set Power supply or line trouble. Remove the quick-disconnect plug between the motor and solenoid (if provided) or detach the two wires where they connect to the solenoid or relay. Virtual Trainer for Online Electrical Skill-Building. If 7. Repair parts such as diodes, fuses, bridge rectifier, etc. Smell the motor for any burned plastic smells. Issues with Mike Szczys. Machine climbing too high above the waterline. In case of power off, users can carry out maintenance by visual check, smelling, asking and measuring. This magnetically locks the rotor in the position shown, because unlike poles attract. Lock out and tag out all electrical circuits. If there is evidence of threading, you must clean the commutator, clean or Proper care for DC motor units primarily consists of regular, thorough inspections, with a focus on the following priorities: long commutator service life, minimal arcing and destructive sparking, Indicates that the DC bus voltage fails to reach 24VDC within 10 seconds of activating the key switch. honda bf150 outboard service and repair manaul. Feel the motor housing with the back of your hand to determine if it's hot (be careful not to burn yourself). This book ws developed in conjuction with EASA's two-day Fundamentals of DC Operation & Repair Tips seminar. After ensuring correct connection, connect it with the power and try to rotate the throttle. Manufacturer's Name the name of the company the made the motorModel and Serial Number information that identifies your particular motorRPM the number of revolutions the rotor makes in one minuteHorsepower how much work it can performWiring diagram how to connect for different voltages, speeds and direction of rotationMore items Remove the springs and brushes by removing the cover typically with a slotted dcrew PRELIMINARY CHECKING Before electrical testing check for proper engine speed/hertz adjustment.

Most motors are designed to run in an ambient temperature of less than 40C. (Note: A properly operating motor may be hot to Electric motor test & repair guide: This article describes A/C electrical motor troubleshooting: here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor problems for motors found on HVAC equipment in buildings such as air conditioners, furnace or air handler blower fans, oil burner motors, well pumps, and While a lot of companies claim to care about quality, Tekwell can stand behind their Learners will perform essentially the same tasks using virtual trainers that they would perform using

Let YORK help you get your machine Up and Running! must be repaired before power is applied to the motor Mechanical problems with the motor or driven equipment. With nearly 50 years in the hydraulic industry, and having a staff with over 300 years of hydraulic experience, Mason Dynamics specializes in what others are afraid of. A multi-meter that can test for DC power. troubles in armature. At Precision Electric, we believe not only in great products, but excellent service as well. Mechanical problems such as worn bearings or a broken pinion could cause a mechanical overload. List the various types of stepper motor drives and explain how to troubleshoot these systems. Visual check: Open shell of the power supply to check whether the power fuse has been blown. 1. After completing this workshop attendees will have a good working knowledge regarding ac & dc motor operation, application, maintenance and testing focused on best-practice procedures. With a DC motor, a variation in speed or torque can be accomplished in two different ways. Fault code 9024. Maintain a proper maintenance period to ensure that the commutator remains troubles in commutator. Attach wire beyond joint temporarily mechanically to motor in some way so wire to motor connection cannot move - you could sticky tape wire to motor or wind around motor a If you find a phase-to-ground short, a motor shop may be able to do an in-place repair for a large motor. FSIP also offers engineered electric system design and general repair services. Direct Current Motor Troubleshooting Based on the EASA TechNote Troubleshooting DC Motors CAUTION ALWAYS Disconnect the power before handling any parts of the electrical equipment. Having minor or major trouble with your Dyson vacuum cleaner? The master switch may be turned off and if that is the case you just need to switch it back on. Known as the heart of the EZGO golf cart, the controllers core objective is to control the speed of the golf cart. With a power inverter, you can use the devices that require AC instead of