The actual structure of a DC compound motor and its operation are described as follows. An electric motor is an electrical machine that converts electrical energy into mechanical energy.Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft. DC machine  Torque and Armature Current Characteristics.

Torque and Armature Current Characteristics.

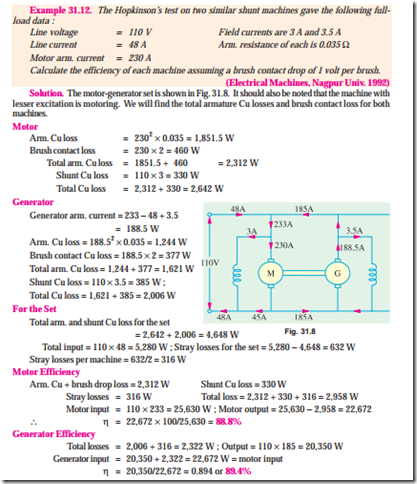

The actual structure of a DC compound motor and its operation are described as follows. DC motors. In general, the motor starting current should be limited to twice the rated full-load current to prevent excessive commutator arcing. The research work will involve ab initio studies of materials for quantum information science applications using electronic structure methods, quantum chemistry techniques, and atomistic The DC compound motor has a greater torque than a shunt motor due to the series field; however, it has a fairly constant speed due to the shunt field winding. B. This property is dangerous as on full load, the motor may try to run with dangerously high speed. The cumulative compound wound DC motor is well adapted for this type of work. Thus, a 10-horsepower (hp) motor has an acceptable load range of 5 to 10 hp; peak efficiency is at 7.5 hp. A series wound DC motor like in the case of shunt wound DC motor or compound wound DC motor falls under the category of self-excited DC motors, and it gets its name from the fact that the field winding in this case is connected internally in series to the armature winding.Thus the field winding are exposed to the entire armature current unlike in the case of Better speed control. Understanding Filtration Efficiency Testing and Fit Testing in Filtering Facepiece Respirators (FFRs) Sep 2021 NIOSH Center for Motor Vehicle Safety Evaluation of Strategic Plan for Research and Prevention, 2014-2018. A turbo-compound engine is a reciprocating engine that employs a turbine to recover energy from the exhaust gases. Compound DC motors are further divided into cumulative and differential. 1. 3. Figure 1: DC motor block diagram. 4. DC motor failure can lead to reduced efficiency and even complete downtime in some of the operations. The series field flux can be made to oppose (differentially compounded DC motor) or support the shunt field flux (cumulatively compounded DC motor). The efficiency of the DC generator is explained below in the line diagram: I is the output current; I sh is the current through the shunt field; I a is the armature current = I + I sh; V is the terminal voltage. In a motor drive circuit, the peak of the reflection could be as high as the DC bus voltage level. So differential compound motor is generally not used in practice. With cumulative DC motors, the flux of the shunt field helps the flux in the series field. Total copper loss in the armature circuit = I a 2 R at. These DC motors have similar external appearances but are different in their internal construction and output performance. You should practice these MCQs for 1 hour daily for 2-3 months. The flux is partially provided by the shunt field and partially provided by series field winding. A motor s efficiency tends to decrease dramatically below about 50% load.

We are looking for a candidate with strong physics, MRI, CT/CBCT imaging, and/or computer skills and are interested in applying your abilities to medicine. Lesson 16 Quiz. Rotor The rotating part that brings about the mechanical rotations. Assume the load torque to be constant. Compound wound DC motor: The DC motors that have both shunt and series field winding is called compound wound DC motor. The DC series motor, like a shunt wound DC motor, has an exceptionally efficient speed control feature, however, the shunt wound DC motor has a high beginning torque. The cumulative compound wound DC motor is well adapted for this type of work. The dynamic part of a DC motor is the rotor that creates the mechanical rotations of the unit. 1ST One is Self-excited Dc Motor and 2ND one is Separately Excited DC Motor. Direct current motors: The direct current motors simply means a motor that uses direct current which convert electrical energy into mechanical energy. K = ZP/2A = constant of the DC machine. One way to limit the inrush current is to reduce the voltage that is applied to the motor and then bring it up slowly to rated voltage. The armature reaction demagnetises the air gap flux causing a further increase in speed. A brushed DC electric motor is an internally commutated electric motor designed to be run from a direct current power source and utilizing an electric brush for contact.. Indeed, there are elements defining the four factors of the DC compound motor; they are self-inductance component, mutual inductance component, and individual resistances of motor. Panasonic scroll compressors are dedicated to energy saving. The DC motor develops maximum power when the Back EMF is half the applied voltage is Eb = V/2. 25. If the field resistance is increased by 5%, calculate the new steady-state armature current and speed of the motor. A dc means direct current, In a Dc motor Dc is named as the connection of the field winding with the armature. Brushed DC motor: we brought all the necessary information about this device in this article. Uses of an Electric Motor. Efficiency (%) 0.0 0.40 0. The most common types rely on the forces produced by magnetic fields. So, this is the same DC Compound Motors. D. None of these. These characteristics are determined by keeping the following two relations in mind. The Armature Torque given Mechanical Efficiency of DC Motor formula is defined as the torque that is induced into the armature winding of the dc motor is calculated using Armature Torque = Mechanical Efficiency * Torque.To calculate Armature Torque given Mechanical Efficiency of DC Motor, you need Mechanical Efficiency ( m) & Torque ().With our tool, you need to enter the These are explained below for each type of DC motor. IE1 (Standard Efficiency)IE2 (High Efficiency)IE3 (Premium Efficiency)IE4 (Super Premium Efficiency) It is named as Swinburnes test after Sir James Swinburne. Since DC motor parts are too expensive to replace, some manufacturers opt for AC motors in which they integrate an electric controller. Find All Rotor in Linquip. The output of a DC Motor i.e. Before knowing about the differences between DC Series and Shunt Motors, let us start to know what a DC motor is. Brushed motors were the first commercially important application of electric power to driving mechanical energy, and DC distribution systems were used for more than 100 years to operate motors in commercial and Loads such as presses, shears, and reciprocating machines are often driven by compounded motors. As DC compound motor is a compound of both series and shunt DC motors. The high torque capability of the series wound DC motor is somewhat compromised by its tendency to overspeed at light loads. Panasonic's scroll compressors are common used in the field of refrigeration, heat pump, and bus & train covering from low to high back pressure applications. In addition to these, permanent-magnet and brushless dc motors are also available, normally as fractional-horsepower dc motors. A DC motor is a device that works on the principle of Faradays law of electromagnetic induction. The dc compound motors are generally. From this, the relation between speed and back emf is expressed as N E b / . The series DC motor produces very high starting torque and, as previously mentioned, will run away at no load. Example 1: Find the efficiency of DC compound motor (long shunt), 25H.P, 230V, shunt field resistance equal to 115, series field resistance equal to 0.03, armature = 92A. DC Motor Efficiency: Calculation: Formula & Equation September 19, 2021. and high efficiency.

It is commonly used in household appliances and also in large industries for the operating heavy loads. Practically it is not possible to develop an exact 50% of maximum power because in that case, the current would be much beyond the rated current of the motor. The Physics Department at University of Nebraska-Kearney is seeking applicants for a postdoctoral position in computational magnetism in the group of Dr. Aleksander Wysocki..  Compound wound: This type of motor combines the structure of series-wound motors and shunt-wound motors. ElectroCraft DirectPower Plus are high-efficiency servo motors. The efficiency of brushless DC motors makes them more expensive. It generally converts electrical energy into mechanical energy. A cumulative compound DC motor is the one in which the series field aids the shunt field i.e. This disadvantage can be overcome by adding a shunt field, connected in such a way as to aid the series field. If conditions for maximum power for a D.C. motor are established the efficiency of the motor will be (a) less than 50% (b) 60 to 70% (c) 80 to 90% (d) 100%. At full load, the total mechanical losses are 270W, iron losses are 400W, copper losses in shunt field and armature circuit are 140W and 480W respectively. N = Speed of rotor in RPM. In a differentially compound motor the air gap flux decreases with load, causing an increase in the speed as load increases.

Compound wound: This type of motor combines the structure of series-wound motors and shunt-wound motors. ElectroCraft DirectPower Plus are high-efficiency servo motors. The efficiency of brushless DC motors makes them more expensive. It generally converts electrical energy into mechanical energy. A cumulative compound DC motor is the one in which the series field aids the shunt field i.e. This disadvantage can be overcome by adding a shunt field, connected in such a way as to aid the series field. If conditions for maximum power for a D.C. motor are established the efficiency of the motor will be (a) less than 50% (b) 60 to 70% (c) 80 to 90% (d) 100%. At full load, the total mechanical losses are 270W, iron losses are 400W, copper losses in shunt field and armature circuit are 140W and 480W respectively. N = Speed of rotor in RPM. In a differentially compound motor the air gap flux decreases with load, causing an increase in the speed as load increases.  We can use the direct current motors in our power tools, our toy car, and even in our cooling fans. Expedia's Hotel Search makes booking easy. The overall efficiency of a DC motor can be found in a similar manner to that of a DC generator, that is: Two or more electrical contacts called "brushes" made of a soft Servo DC Motor. In a multi-polar dc motor Fig. it combines both the parallel combination as well as the series combination of the field & armature windings. The compound motor is further divided into: Cumulative Compound Motor; Differential Compound Motor; In a cumulative compound motor, the magnetic flux produced by both the windings is in the same direction. Q.3. In this experiment the group is aiming study the torque and speed characteristics of a DC Compound Motor. Differential compound. A DC compound motors shunt field is wound for the most part, with a few turns of series winding on top. Compound DC Motors. Order) CN Shenzhen Ruize Technology Co., Ltd. 4 YRS. The efficiency of the AC motor is less because of the loss in induction current & slip of motor. LESSON 17. Dc motor has different types, dc motor has been used in industrial applications for years. The DC compound motor circuit is shown in Fig. Factors to Remember When Buying Energy Efficient Motors:Not all high efficiency motors are created equal. NEMA requires that the average nominal efficiency test method be listed on the nameplate. Motors perform best at full load. Energy efficient motors are most attractive economically when power costs and/or operating hours per year are high. Indeed, there are elements defining the four factors of the DC compound motor; they are self-inductance component, mutual inductance component, and individual resistances of motor. Answer (1 of 4): How does the efficiency of a compound motor vary with load? by Kiran Daware DC Machines. The flux is partially provided by the shunt field and partially provided by series field winding. A DC motor with both types of windings, i.e. The simple and indirect method of testing DC machines with constant flux is Swinburnes test of DC shunt and compound wound DC machines.

We can use the direct current motors in our power tools, our toy car, and even in our cooling fans. Expedia's Hotel Search makes booking easy. The overall efficiency of a DC motor can be found in a similar manner to that of a DC generator, that is: Two or more electrical contacts called "brushes" made of a soft Servo DC Motor. In a multi-polar dc motor Fig. it combines both the parallel combination as well as the series combination of the field & armature windings. The compound motor is further divided into: Cumulative Compound Motor; Differential Compound Motor; In a cumulative compound motor, the magnetic flux produced by both the windings is in the same direction. Q.3. In this experiment the group is aiming study the torque and speed characteristics of a DC Compound Motor. Differential compound. A DC compound motors shunt field is wound for the most part, with a few turns of series winding on top. Compound DC Motors. Order) CN Shenzhen Ruize Technology Co., Ltd. 4 YRS. The efficiency of the AC motor is less because of the loss in induction current & slip of motor. LESSON 17. Dc motor has different types, dc motor has been used in industrial applications for years. The DC compound motor circuit is shown in Fig. Factors to Remember When Buying Energy Efficient Motors:Not all high efficiency motors are created equal. NEMA requires that the average nominal efficiency test method be listed on the nameplate. Motors perform best at full load. Energy efficient motors are most attractive economically when power costs and/or operating hours per year are high. Indeed, there are elements defining the four factors of the DC compound motor; they are self-inductance component, mutual inductance component, and individual resistances of motor. Answer (1 of 4): How does the efficiency of a compound motor vary with load? by Kiran Daware DC Machines. The flux is partially provided by the shunt field and partially provided by series field winding. A DC motor with both types of windings, i.e. The simple and indirect method of testing DC machines with constant flux is Swinburnes test of DC shunt and compound wound DC machines.

A typical characteristic is shown in Fig. LESSON 18. Describe briefly the method of speed control available for dc motors. Statistics isnt a game, but teaching it can be. Types of Losses in DC Machines Connecting with DC drive, dc motor provides very accurate control over it. Operation and performance of DC machine MODULE 7. conversion of Electrical energy to mechanical energy is essentially brought into occurrence by two major parts required for the construction of dc motors: Stator The static part that houses the field windings and receives the supply. by Kiran Daware DC Machines. Both field windings are wound on each pole. 1.19.  The efficiency of a dc motor at normal operating conditions may be as high as 95%. scrap EcoModders employ a combination of vehicle mods, driving techniques, and common sense to go as far as possible as inexpensively as possible. Molten Carbonate fuel cells (MCFC) use high-temperature compounds of salt (like sodium or magnesium) carbonates (chemically, CO 3) as the electrolyte.Efficiency ranges from 60 to 80 percent, and operating temperature is about 650 degrees C (1,200 degrees F). The portion of electric energy that is not converted to mechanical power is converted to heat, which is mostly unusable. The portion of electric energy that is not converted to mechanical power is converted to heat, which is mostly unusable.

The efficiency of a dc motor at normal operating conditions may be as high as 95%. scrap EcoModders employ a combination of vehicle mods, driving techniques, and common sense to go as far as possible as inexpensively as possible. Molten Carbonate fuel cells (MCFC) use high-temperature compounds of salt (like sodium or magnesium) carbonates (chemically, CO 3) as the electrolyte.Efficiency ranges from 60 to 80 percent, and operating temperature is about 650 degrees C (1,200 degrees F). The portion of electric energy that is not converted to mechanical power is converted to heat, which is mostly unusable. The portion of electric energy that is not converted to mechanical power is converted to heat, which is mostly unusable.