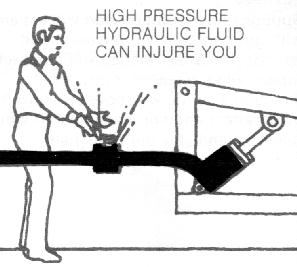

If this hazard exists, restrain or shield the hose using clamps or protective shielding. In a large sheet metal plant, a typical order was being processed on a 200-ton hydraulic press. Always recheck the level of the hydraulic fluid.

If this hazard exists, restrain or shield the hose using clamps or protective shielding. In a large sheet metal plant, a typical order was being processed on a 200-ton hydraulic press. Always recheck the level of the hydraulic fluid.  Our online Hydraulic Safety course has numerous benefits, including: 24/7 course access; Log on. sheet of the hydraulic fluid used, have to be incorporated and implemented into the operating instructions (see section 2.1). Perform regular checks of the oil cooler and outside the reservoir to prevent overheating. Objective: Describe the hazards involved in working with hydraulic equipment and how to prevent incidents. When the time comes to actually place the materials into the press or pump-operated machine, keep your wits about you. Take particular care to mitigate the risk of fluid injection injury. Hydraulic systems store fluid under high pressure.

Our online Hydraulic Safety course has numerous benefits, including: 24/7 course access; Log on. sheet of the hydraulic fluid used, have to be incorporated and implemented into the operating instructions (see section 2.1). Perform regular checks of the oil cooler and outside the reservoir to prevent overheating. Objective: Describe the hazards involved in working with hydraulic equipment and how to prevent incidents. When the time comes to actually place the materials into the press or pump-operated machine, keep your wits about you. Take particular care to mitigate the risk of fluid injection injury. Hydraulic systems store fluid under high pressure.  Forklift Hydraulics. Move the hydraulic lever back and forth a few times to release residual pressure. Hydraulic Hose Safety.

Forklift Hydraulics. Move the hydraulic lever back and forth a few times to release residual pressure. Hydraulic Hose Safety.

Know the hazards that could occur from working with hydraulic equipment and how to prevent them. 2. Because almost every application uses an enclosed system for storing and transferring hydraulic fluid. $ Register Now .  Check that all pipework is securely attached and maintained and that hoses are connected properly and are free from leaks. Hydraulic systems are used to lift implements, such as plows; to change the position of implement components, such as a combine header or bulldozer blade; to operate remote hydraulic motors, and to assist steering and braking. Hydraulic presses are tools, not toys. Avoid Contamination of Your Hose Assembly. This occurs when a person is struck by a high-pressure stream of hydraulic fluid, injecting it into their body. Lower hydraulically powered attachments to the ground, or support them on suitable metal stands or blocks. Hydraulic Safety TOOLBOX TALK We are all surrounded by hydraulics every day. S a F e T Y.

Check that all pipework is securely attached and maintained and that hoses are connected properly and are free from leaks. Hydraulic systems are used to lift implements, such as plows; to change the position of implement components, such as a combine header or bulldozer blade; to operate remote hydraulic motors, and to assist steering and braking. Hydraulic presses are tools, not toys. Avoid Contamination of Your Hose Assembly. This occurs when a person is struck by a high-pressure stream of hydraulic fluid, injecting it into their body. Lower hydraulically powered attachments to the ground, or support them on suitable metal stands or blocks. Hydraulic Safety TOOLBOX TALK We are all surrounded by hydraulics every day. S a F e T Y.

Many injuries and deaths occur because workers are poorly trained and ill-informed about hydraulic power. One of the most severe hazards associated with hydraulic system is injection injury. To stop the power unit you must first de-energize the hydraulic system (turn hydraulic control valve counter-clockwise). Pressurized fluid can penetrate the skin, requiring prompt surgical removal. Upon completing this Hydraulic System Course successfully, participants will be able to: Learn the basic structure of hydraulic systems. Most hydraulic systems must store fluid under high pressure. Safety. A list of Preventive Maintenance Task for a Hydraulic System could be: 1. Hazard warnings and safety measures, among others from the safety data . Easy of accuracy and control Variable speed. If you use a water-based hydraulic fluid, dont let the temperature go below 140F, so the water does not evaporate from the fluid. Where: SSM (3-1680 Notre Dame Ave, Winnipeg) Cost: $595. The operators/ maintenance crews are subjected to hazards from high pressure liquids and large mechanical forces. Hydraulic Fluid Risks There are dangers linked to using hydraulic fluid in the system, which can be stored up to a pressure of 2,000 pounds per square inch. Download PDF. You will also review a method for creating and verifying a zero energy state, so that a system can be worked on safely. draulic fluid used in the system. They can control the pressure in the main system or in isolated sub-circuits. This lesson identifies common hazards, including heat, flammability, pinch points, hose and fitting failures, dangerous system adjustments, and unexpected motion. This lesson identifies common hazards, including heat, flammability, pinch points, hose and fitting failures, dangerous system adjustments, and unexpected motion.

Any hydraulic system is inherently dangerous, as an enormous amount of energy is transmitted through the high-pressure system. hydraulic systems fail, from falling loads or unexpected moving parts. Check that all pipework is securely attached and maintained and that hoses are connected properly and are free from leaks. When performing maintenance there is the potential of being exposed to three kinds of hazards: Cuts, bruises, or even fractured limbs caused by flailing hydraulic hose. * AE documents are available through S SAE Customer Service at: (phone) 724-776-4970 (fax) 724-776-0790. The hydraulic fluid is under tremendous pressure that can exceed 2,000 pounds per square inch (psi), according to a report on hydraulic safety at. LunchBox Sessions is a new take on online industrial training, full of interactivity, used by individuals, schools, and companies around the world. Hydraulic System. Trainers Note Many implements use a hydraulic system. To stop the hydraulic power unit slow the engine down before stopping the engine. The TP 205 training package for safety in pneumatic systems coves the following topics: Pneumatic safety circuits Electrical safety circuits on Hydraulic System Safety. Expand Fullscreen. April 27, 2022. This safety -focused course explains the hazards of hydraulic systems and teaches workers how to prevent avoidable accidents. The safety of personnel must be ensured while they are operating and maintaining hydraulic systems. Also, most hydraulic fluid is toxic, and can be harmful to the skin, eyes, and the environment. Three kinds of hazards exist: burns from the hot, high pressure spray of fluid; bruises, cuts or abrasions from flailing hydraulic lines; and injection of fluid into the skin. Leakage of fluids may cause ignition of fire hazards. A number of questions need to be addressed regarding hydraulic safety in hydraulic systems. At Bernell Hydraulics, we offer a complete range of hydraulic services including 24 hour on site repair service. Hydraulic fluid needs to remain under 180 degrees Fahrenheit in temperature. And like any tool, if improperly used, they can cause accidents sometimes even if you think you're being safe. Due to the nature of the hydraulic press and its functions, the most common workplace injuries involve hands and fingers. The system provides a solid basis for practice oriented training and vocational education. 12. Trapped fluid can be pressurized in excess of 2,000 psi. Hydraulic safety knowledge and respect for the hazards of hydraulics is gained through training and mentoring; however, the practice of learn as you go is an unacceptable way to gain safety knowledge. To know the hazards that could occur from working with hydraulic equipment and how to prevent them. Change out hose assemblies and quick-connect systems at the same time. Maintenance and safety considerations for high-pressure hydraulic hose assemblies in ground support equipment. #1: Only operate the system for its intended purposes. We can prevent severe health and safety hazards by emphasizing proper safety > precautions like. Take particular care to mitigate the risk of fluid injection injury. One final safety tip for working with hydraulic fluids is to simply turn to the pros whenever your equipment needs service or repair. Previous Document. Loss of pressure: This may sound like more of an inconvenience than anything, but improperly working equipment always has the potential for danger. In some systems, its necessary for sub-circuits to operate at different pressure to others. If safe isolation procedures are not followed then electrical, hydraulic or pneumatic systems can exhibit risks such as: Uncontrolled movements or dangerous load conditions, others turning the power back on before work is finished, trapped in pressure, damaging negative pressures, loss of fluid or contamination entering the system. sheet of the hydraulic fluid used, have to be incorporated and implemented into the operating instructions (see section 2.1). There are dangers linked to using hydraulic fluid in the system, which can be stored up to a pressure of 2,000 pounds per square inch.

10. Hydraulic systems may contain potentially hazardous energy that requires the employer to "bleed off" the pressure. Plant arms or equipment can cause injury through rapid movement or slow movement without the worker being aware of the danger. To register: Call 949-1085. Any hydraulic system is inherently dangerous, as an enormous amount of energy is transmitted through the high-pressure system. Hydraulic pressure systems pose many hazards that may be overlooked. The danger in working on hydraulic systems is they are under high pressure, typically 2,000 PSI or more, and are also at high temperature.

Compact Quiet The safety of personnel must be ensured while they are operating and maintaining hydraulic systems. Three kinds of hazards exist: burns from the hot, high pressure spray of fluid; bruises, cuts or abrasions from flailing hydraulic lines and hydraulic injection of fluid into the skin. Hydraulic System. Hydraulic Oil Safety.

Most hydraulic systems run in the 110-150F range with mobile hydraulic systems running up to 250F. Safe working habits around hydraulic systems save lives. Review hazards of working with hydraulic systems and how to prevent incidents. A heated petroleum based hydraulic fluid presents a considerable fire hazard, particularly in those processes where ignition sources are usually present. en Hydraulic systems

The operator needs to be very careful with them. F = 1500 lbf/in. One type of problem in the hydraulic system is contamination. View Hydraulic Safety PPTs online, safely and virus-free! Burns from hot/high-pressure fluid. burns from the hot, high pressure spray of fluid; bruises, cuts or abrasions from flailing hydraulic lines and hydraulic injection of fluid Working a hydraulic hammer is like being next to a fully operative gun range in action. Where: SSM (3-1680 Notre Dame Ave, Winnipeg) Cost: $595. Learn new and interesting things. A forklift hydraulic system is the heart of the machine because it is responsible for moving pallets. Hazard warnings and safety measures, among others from the safety data .

When: October 20. Join Discussion. Trainer's Note: Many farm implements use a hydraulic system. Hydraulic systems store fluid under high pressure. The levers control the hydraulic system in a forklift. Energy hazards from sources such as electrical and pressure vessels have standards that are very well advanced compared to current hydraulic safety standards. Hydraulic fluid is dangerous. Hydraulic system pressure often exceeds 2000 pounds per square inch (psi). Remodeling machines and systems can constitute a substantial modifica-

A history of incidents does exist and IHSA has found there is a lack of standards with regards to; system assemblies, safety, inspections, education, identification, and certifications. Use Common Sense When the Press or Pump is Moving. CEJN also recommends that users pressure-test hose assemblies at two-year intervals (at 1.5 working pressure) and totally replace assemblies every six years. involving hose assemblies in hydraulic systems. You should never attempt to use a hydraulic system in a manner it was not designed to do. Reversible Absence of vibration.